TTC100 cable setter system includes the Z-axis zero tool setter unit, 20mm thick mounting base,blow-cleaning device(optional), and standard measuring software. The TTC100 CNC Z-axis zero tool setter is a length tool setter in cnc z axis tool setter. TTC100 CNC tool zero setter is triggered when a tool touches the contact face. A trigger signal of cnc tool zero setter is sent to the machine tool controller via the hard-wired cable and the tool length is automatically calculated. Pioneer, a professional CNC Z axis tool setter supplier in China, can provide you with high-precision CNC Z axis zero tool. If you are interested in our TTC100 CNC Z-axis zero tool setter, welcome to contact us!

TTC100 cable setter system includes the Z-axis zero tool setter unit, 20mm thick mounting base,blow-cleaning device(optional), and standard measuring software. The TTC100 CNC Z-axis zero tool setter is a length tool setter in cnc z axis tool setter. TTC100 CNC tool zero setter is triggered when a tool touches the contact face. A trigger signal of cnc tool zero setter is sent to the machine tool controller via the hard-wired cable and the tool length is automatically calculated. Pioneer, a professional CNC Z axis tool setter supplier in China, can provide you with high-precision CNC Z axis zero tool. If you are interested in our TTC100 CNC Z-axis zero tool setter, welcome to contact us!

TTC100: | |

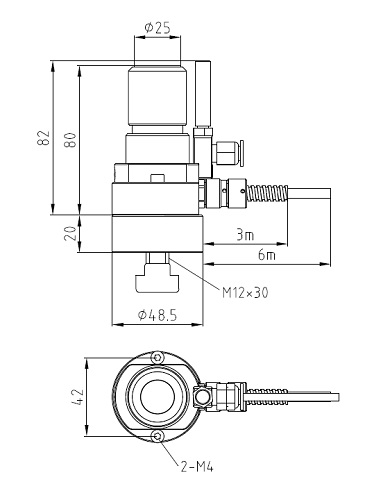

Measuring direction | -Z, 5mm |

Nominal height of the TTC100 tool setter | 80mm |

Repeatability (2σ) | ≤ 2 μm; |

Diameter of the touching face | 25.0 mm |

Hardness of the touch face | HRA 90-93 |

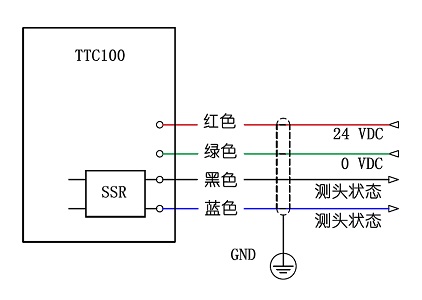

Input voltage | 24±10% VDC |

Output load current | 50 mA |

Seal grade | IP68 |

TTC100 sets lengths parameter of cutting tools automatically on various types of CNC machine tools

TTC100 tool setter can detect tool wear and breakage automatically between two processes or after the CNC processing;

TTC100 tool setter can control the change of machining precision from the temperature change of the machine by checking cutting tool length.

Tool setter transmits a signal through cable, reversal connecting tool setter's power supply can reverse the state of the output signal;

There are two installing and fixing methods, one is to install directly, the other is to add a mounting base of 20mm thick, the tool setter's height can be raised from 80mm to 100mm.

One LED indicator light is used to display the tool setter's working state.

Thank you for your attention on TOUCH PROBE & SETTER SYSTEM

Other Cable Tool Setter System