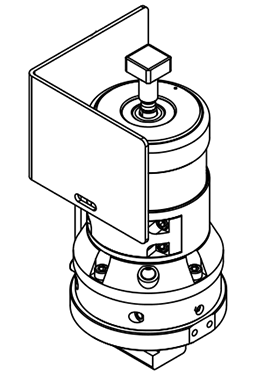

RP610T radio tool setter is a wireless tool setter, radio coded signals are used to transmit information between the tool setter and the receiver. It is suitable for use on machining centers of all sizes and in applications where line-of-sight between the tool setter and receiver is difficult to achieve. It offers users broken tool detection and rapid measurement of tool length and diameter on a wide range of tools.

RP610T radio tool setter is a wireless tool setter, radio coded signals are used to transmit information between the tool setter and the receiver. It is suitable for use on machining centers of all sizes and in applications where line-of-sight between the tool setter and receiver is difficult to achieve. It offers users broken tool detection and rapid measurement of tool length and diameter on a wide range of tools.

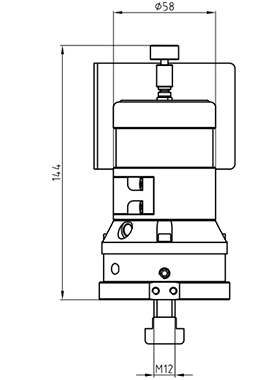

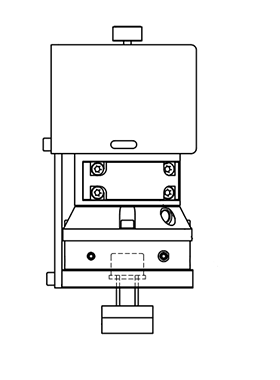

RP610T: | |

Measuring direction | ±X,±Y,+Z |

Arbitrary direction swinging angle | X-Y±15°, Z +5 mm |

Repeatability (2σ) | ≤ 2 μm; |

Trigger force in the Z direction | 600±30(g) |

Trigger force in the X-Y direction | 50-100(g) |

Radio signal receiving/sending distance | >14m |

Model of the standard stylus | M0-S25-CPF16 |

Model of the battery | 14250,3.6 (V), 2 Pcs |

Seal grade | IP68 |

Tool setter switch on/off method: M code on/off;

Compatible with Pioneer radio modulated receivers OSI-20M ;

Superior communication capability. ◆ Globally recognized 2.4 GHz waveband – compliant with radio regulations in all major markets.

Fast and accurate on-machine tool setting and broken tool detection.

It can be used stand-alone or as part of a multi-probe system, enabling use in a wide range of applications.

Automatically stop the process when broken tools are detected.

Reduce non-productive time and scrap and increase productivity and profits.

Thank you for your attention on TOUCH PROBE & SETTER SYSTEM

Other CNC Tool Setter System