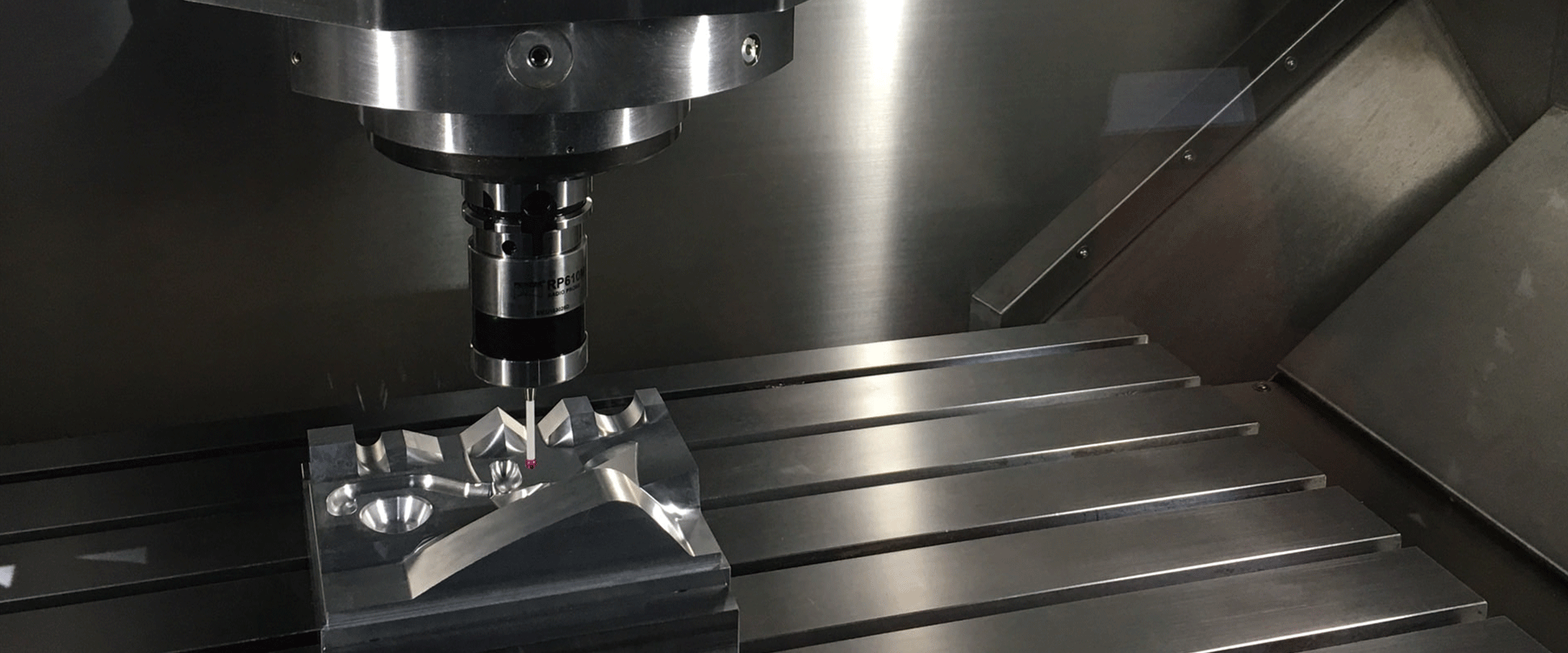

CNC Machine Tool Touch Probe System

Pioneer touch probes for CNC machines can measure and find the base position of the workpiece quickly and accurately, set or modify the workpiece coordinate automatically. The CNC machine touch probe system is an effective solution for improving the accuracy of your workpieces and the productivity of your manufacturing lines. Pioneer probes deliver significant cost savings, and improvements in quality, for all applications using machine tools throughout aerospace, automotive, electronics and other industries. Pioneer offers several series of touch probe systems--Radio probe system, optical probe system, cable probe system and manual probe. Feel free to contact us to get the CNC touch probe price!

Pioneer is a professional CNC touch tool measuring probe manufacturer and supplier. We can offer you the most suitable CNC touch probes with high-quality according to your needs. Pioneer touch probes for CNC machines has premium quality and satisfaction guarantee. And our CNC touch probe price is reasonable. If you want to buy CNC touch probes, Please feel free to contact us to get CNC touch probe price and more information. Choose us!

Types of CNC Machine Tool Probe System

-

Radio Probe SystemThe radio communication probe system is suitable for various complex working conditions in the processing of CNC machine tools.View More

-

OPS-30 Optical CNC Probe SystemOPS-30 optical probe system mainly used in various specifications of machine center, CNC milling machine, drilling machine center and so on. OPS-30 optical probe system contains OP510 optical probe, OSI-20 receiver and standard measuring software.View More

-

Cable CNC Probe SystemThe cable probe system is suitable for various complex working conditions in the processing of CNC machine tools, mainly suitable for small machine tools, grinding machine, lathe machine and so on.View More

-

Manual ProbeThe manual probe is suitable for various specifications of machine centers, CNC boring and milling machines, drilling-tapping machine centers, etc. Manual probe is an economy probe.View More

Advantages of Touch Probe System & Software

-

Optimize machining allowance control to ensure the quality and consistency of batch products;

Optimize machining allowance control to ensure the quality and consistency of batch products; -

Simplify or cancel special fixture and reduce the production cost;

Simplify or cancel special fixture and reduce the production cost; -

Shorten the auxiliary time of the machine tool and improve the production efficiency

Shorten the auxiliary time of the machine tool and improve the production efficiency -

Reduce the manual operation, reduce labor intensity and the influence of human operation factor to the product processing precision.

Reduce the manual operation, reduce labor intensity and the influence of human operation factor to the product processing precision.

FAQs of Touch Probe System For CNC Machines

-

What's the role of CNC machine tool probe?

Touch probes for CNC machines can measure and find the base position of the workpiece quickly and accurately, set or modify the workpiece coordinate automatically. CNC machine tool probe can also realize the on-machine detection of the corresponding machining parts through the network technology, and provide the corresponding machine tool measurement error compensation to ensure that the corresponding data of the workpiece reaches the standardized production

-

How does a CNC touch probe work?

After the CNC machine tool is produced, the CNC machine tool probe will measure and test the corresponding metal mold parts again through its own measurement software, and digitizing probe would display the corresponding measurement data into a digital report directly in front of the operator, and cnc digitizing touch probe automatically return the unqualified products for compensate processing and production to ensure a 100% pass rate of machine metal mold parts.

-

How to select CNC machine tool probe?

1. Enterprises can choose probes flexibly according to processing needs. In addition, the machine tool probe can also be selected according to the complexity of the processing.

2. As an important component of the machine tool probe measuring system, the stylus will directly affect the measurement results of the machine tool probe in cnc measuring. So companies can use the stylus as a reference when selecting probes in measurement touch probe.

-

What is a touch probe?

The CNC machine tool probe is a measuring device equipped on a CNC machine tool, and machine tool measurement can be installed on most CNC machine tools such as CNC lathes, machining centers, and CNC grinders. Without human intervention in the processing cycle, the size and position of the tool or workpiece are directly measured, and the offset of the workpiece or tool is automatically corrected according to the measurement result, so that the same machine tool can process more high-precision parts.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  tiếng việt

tiếng việt  Nederland

Nederland