OPS-30 optical probe system with special cnc probe programming contains xyz probe cnc-OP510 optical infrared probe, OSI-20 receiver and standard measuring software. The OP510 CNC xyz touch probe is a compact 3D touch-trigger probe with optical signal transmission.Cnc xyz probe can be used for workpiece measuring. Optical transmission probe is widely applied. OPS-30 optical transmission probe system mainly used in various specifications of machine center, CNC milling machine, drilling machine center and so on.

OPS-30 optical probe system with special cnc probe programming contains xyz probe cnc-OP510 optical infrared probe, OSI-20 receiver and standard measuring software. The OP510 CNC xyz touch probe is a compact 3D touch-trigger probe with optical signal transmission.Cnc xyz probe can be used for workpiece measuring. Optical transmission probe is widely applied. OPS-30 optical transmission probe system mainly used in various specifications of machine center, CNC milling machine, drilling machine center and so on.

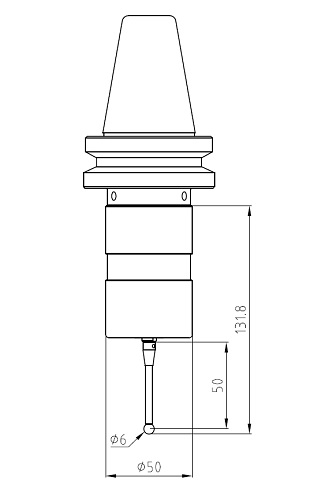

OP510: | |

Measuring direction | ±X,±Y,+Z |

Arbitrary direction swinging angle | X-Y±12°, Z +5 mm |

Repeatability (2σ) | ≤ 2 μm; |

Trigger force in Z direction | 600±30(g) |

Trigger force in X-Y direction | 40-80g) |

Optical signal receiving/sending distance | >5m |

Model of the standard stylus | M4-P50-RB6-S36 |

Model of the battery | 14250,3.6 (V), 2 Pcs |

Seal grade | IP68 |

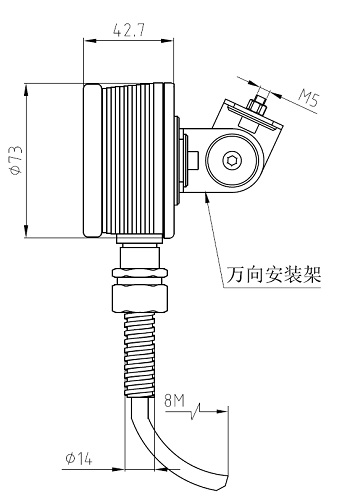

OSI-20: | |

Optical signal receiving/sending distance | >5m |

Input voltage | 24±10% VDC |

Output load current | 50mA |

Length of the cable | 8m |

Length of the cable retaining tube | 2m |

Seal grade | IP68 |

Optical probes are suitable for small and medium-sized milling machines and machining centers with automatic tool change.

Optical probe are used to set work-piece coordinate system and machining zero points

Optical probe are used to detect and control the key dimensions, position coordinates and their precision automatically between two processes

Probe switch on/off method::Range on/off、M code on/off;

Infrared coded signals are used to transmit information between the probe and the receiver;

The transmitting distance of the probe signal can be adjusted by trigger probe with special program to set the receiver;

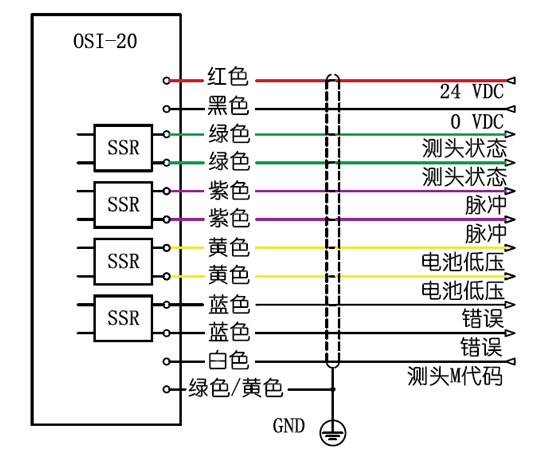

Output four kinds of SSR signals to machine control system when probe is in the states of trigger、error、probe batteries low and output pulse;

The OSI-20 receiver can change its logical state of the output signal by setting;

Double infrared signal receiving and transmitting devices are used to increase the reliability of the equipment;

The LED lights in the receiver show the working status of the probe system.

Thank you for your attention on TOUCH PROBE & SETTER SYSTEM

Other Touch Probe System